How to Control the Movement of Liquids In Microfluidic Devices

Flow Control in Microfluidics:

Microfluidics is an exciting and growing field of science that deals with the control of minute amounts of liquid. By using miniature devices, scientists can direct the flow of these liquids in precise ways that would be impossible to achieve with larger setups. In this article, we will discuss the basics of flow control for microfluidic devices, and how precision pressure regulators can be used to achieve optimal results.

Systems for microfluidic flow control:

Peristaltic pumps and recirculation pumps

When microfluidic devices require continuous sampling, researchers use peristaltic pumps or recirculation pumps. Due to their lack of precise control overflow, these pumps are gradually being less and less used in microfluidics. Researchers more often use a syringe pump or a pressure-controlled recirculation setup when recirculation is needed.

Syringe pumps

Researchers are increasingly turning to alternative flow control systems to replace syringe pumps. We can divide syringe pumps into two groups. Classic syringe pumps, which generate flow oscillations in the case of microfluidics, and pulseless microfluidic syringe pumps which clearly deliver better performance in terms of flow stability. Here, we will only discuss pulseless microfluidic syringe pumps. As an alternative, common syringe pumps can be used however, be aware that the flow will not be stable at low flow rates.

Syringes are extremely easy to use. That is their main advantage. The main weakness of pulseless syringe pumps is their low responsiveness, since they depend on microfluidic setups. Microfluidic chips can change flow rate in seconds to hours.

Pressure controllers with flow meters

A pressure controller is a device that controls the flow in the tank containing your sample. By introducing the sample into a microfluidic chip under pressure, the sample is smoothly injected. The majority of microfluidics research is done by using pressure controllers because they can establish pulseless flows with fast response times (80 ms) in microfluidic chips. The pressure-driven flow setup propagates changes in pressure in the fluidic set up without delay, allowing fast flow switching. The smooth operation of pressure-driven flows is further enhanced by the absence of moving mechanical parts. Through the integration of a flow meter and a feedback loop, modern microfluidic pressure controllers can also control both pressure and flow rate. The most common applications for pressure controllers in microfluidics are when researchers require high flow responses and stability and precision, as well as when creating dead-end channels or working with large samples.

Precision Pressure Regulators:

When working with precision pressure regulators, it is important to keep in mind the relationship between pressure and flow. By controlling the pressure exerted on a liquid, you can also control its flow rate. This relationship is important to understand when setting up your microfluidic device, as it will allow you to achieve the desired results.

One of the most important aspects of microfluidics is flow control. Microfluidics deals with very small volumes of liquid, so even a slight change in flow rate can have a big effect on results. For this reason, precision pressure regulators are often used to control the movement of liquids in microfluidic devices. Pressure and flow control are two sides of the same coin: by controlling the pressure exerted on a liquid, you can also control its flow rate.

There are many different types of precision pressure regulators available on the market today. each with its own advantages and disadvantages. The type that you choose will depend on your specific needs and application. However, one thing that all precision pressure regulators have is the ability to provide a very high degree of control over the movement of liquids.

Purchasing a precision pressure regulator for a microfluidic application is an important decision. When choosing a precision pressure regulator, it is important to consider the specific needs of an application. There are many different types of precision pressure regulators on the market, each with its own set of specifications.

Different types of precision pressure regulators offer different advantages and disadvantages. For example, some precision pressure regulators are better suited for high-pressure applications, while others may have a higher degree of accuracy. The type of precision pressure regulator that you choose will depend on your specific needs and application. Here are some things to consider for your application.

-What is the maximum pressure that you will be working with?

-What is the desired flow rate?

-What is the degree of precision that you need?

-What are the space constraints of your application?

Keep these factors in mind when choosing a precision pressure regulator, and you’ll be sure to find one that meets your needs.

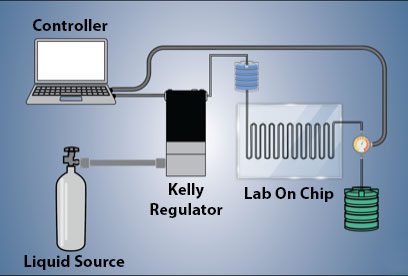

The Kelly Electronic Regulator for Lab-on-a-chip Applications

The Kelly Low Flow Regulator is a perfect solution for using precision pressure control to pilot operate a liquid to control flow at microfluidic flow rates. Since the regulator is pilot-operating a pressure over the liquid, no flow is required to be maintained by the regulator. This means that the regulator can be customized to accurate minute pressure changes smoothly.

One application where this is utilized effectively is Lab-on-a-chip Applications. These applications require extremely accurate low volume and precise rates of fluid to be passed through an integrated circuit. These flow rates can be as low as pico-liters, which are achieved by finely controlling the pilot pressure and passing the fluid through a precision orifice.

Since the Kelly Low Flow Regulator can be controlled dynamically by a control system, this allows for vert fine-tune adjustments to resultant outlet flow rates, meaning manual adjustment is not necessary. This also allows the same regulator to be sued for varying Lab-on-a-chip circuits. By programming a set of accurate pilot pressures to flow rate equations, the Low Flow Regulator can be commanded to be used with numerous circuits.