Semiconductor Manufacturing

Pneumatic Solutions Used In Semiconductor Manufacturing

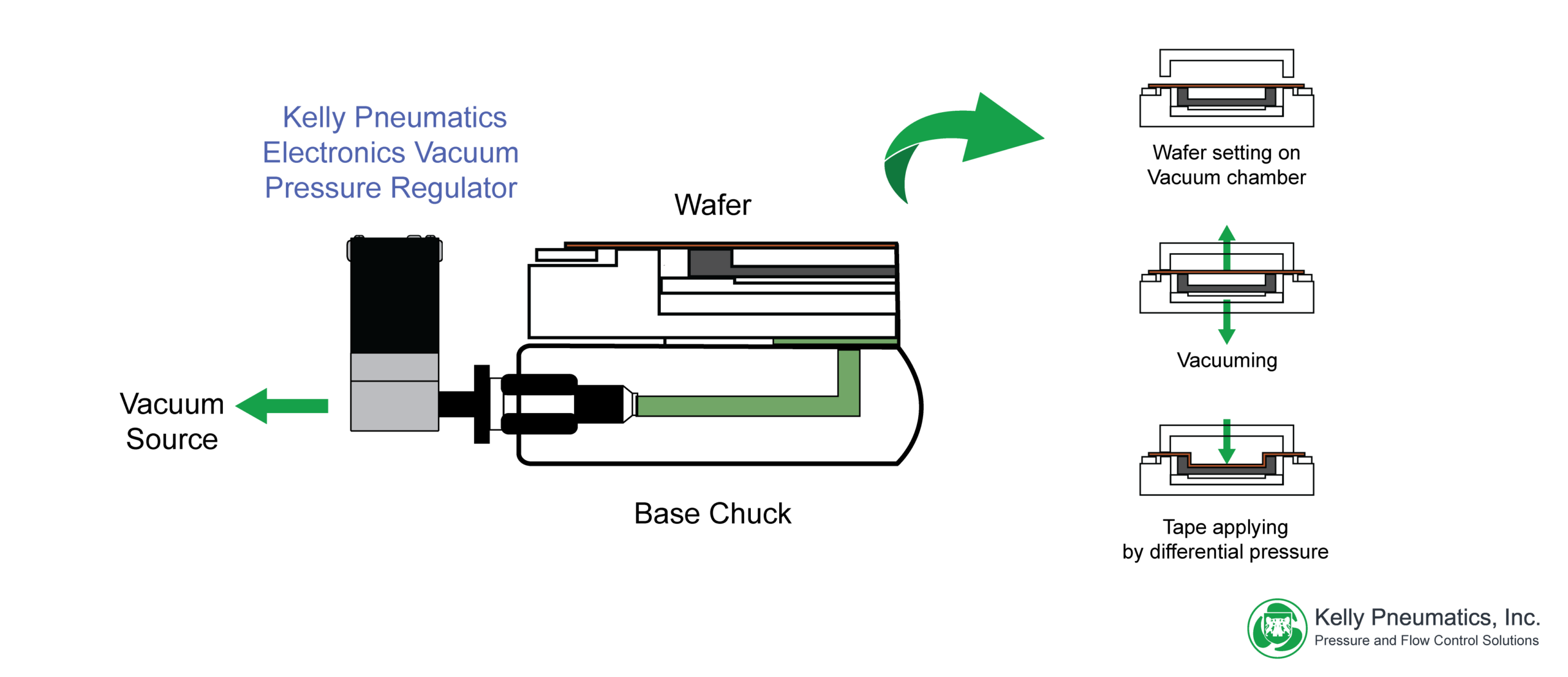

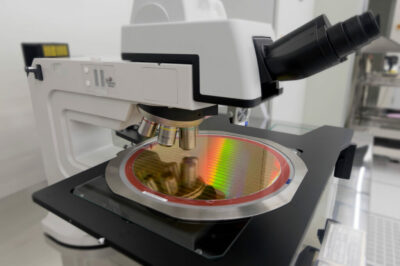

Semiconductors are the foundation of modern electronics and play a crucial role in a wide variety of devices, from smartphones to car engines. Semiconductor manufacturing is a complex and delicate process, and Kelly Pneumatics has years of experience providing pneumatic solutions for this industry. Our pressure regulators provide precise control of air pressure, ensuring that sensitive semiconductor components are not damaged during the manufacturing process. From Wafer Pad Polishing to Wafer Cutting, our products improve control systems in this vital industry.

Applications

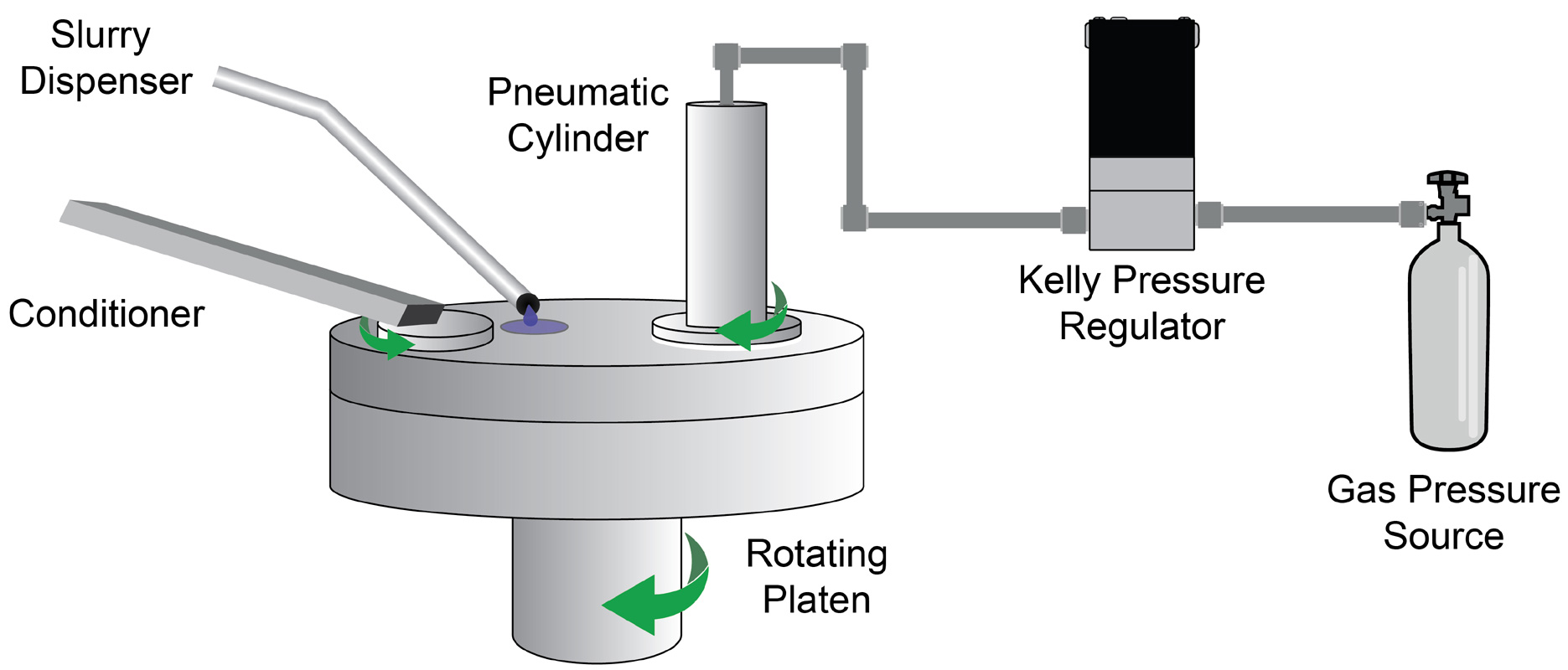

Wafer Polishing

Chemical Mechanical Wafer Polishing is a process that uses a combination of chemicals and mechanical polishing to remove material from the surface of a semiconductor wafer. The chemical component of CMP reacts with the surface being polished, while the mechanical component removes material through physical abrasion.

Wafer Dicing

Semiconductor wafer cutting, also known as wafer dicing, is a key process in the fabrication of semiconductor devices. It is the stage in which individual semiconductor chips are precisely cut from a silicon wafer, preparing them for eventual assembly into products that power our digital world. As demand for high-performance and miniaturized devices continues to grow, the importance of precision in wafer cutting cannot be understated.