Semiconductor Thermal Cycle Testing Techniques

Semiconductor test equipment is a crucial component of the semiconductor industry, as it allows manufacturers to evaluate and test semiconductor integrated circuits (ICs) and chips after they have been manufactured. These tests are critical for ensuring that the ICs and chips meet the required specifications and can perform reliably in their intended applications.

One type of test that is commonly performed on semiconductor ICs and chips is the thermal cycling test. This test subjects the device to a range of temperatures to simulate the thermal stress that it may encounter during its intended use. During the test, the chip is cycled through a range of temperatures, typically starting at a low temperature and gradually increasing to a high temperature.

The chip is monitored during the test for any performance issues or failures that may occur as a result of the thermal stress. The test is typically repeated multiple times to increase the robustness of the test results. To perform this test, a thermal head is used to indirectly apply a thermal load to the chip.

For low temperature testing, flow of a coolant like HFE fluid or Glycol can be used to drastically decrease the temperature of the IC under test very quickly. This can be achieved by using the Kelly Proportional Valve to control the coolant, which allows for precise control of the thermal stress applied to the IC under test.

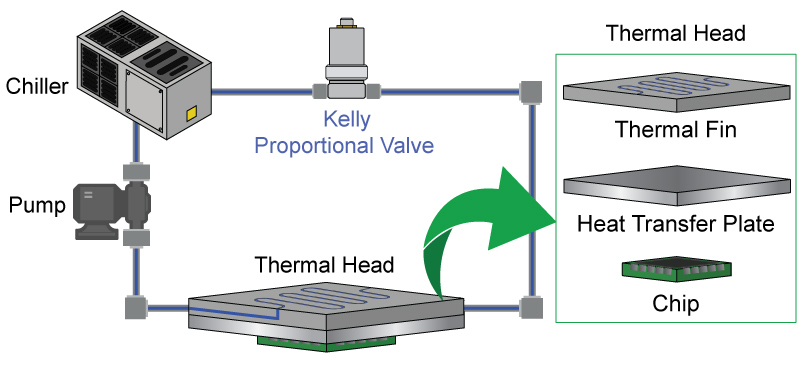

In the simplified diagram above, the HFE or Glycol coolant is processed by a pump and chiller upstream from the Kelly Proportional Valve. The pump is used to circulate the coolant through the system, while the chiller is used to maintain the temperature of the coolant. This ensures that the Kelly Proportional Valve is supplied with enough pressure to continue flowing and that the Glycol remains at the correct temperature throughout the test.

The Kelly Proportional valve is used to control the flow of the HFE coolant through the thermal head, allowing for precise control of the thermal gradient and ensuring that the chip is subjected to the correct thermal stress. By adjusting the flow rate of the HFE coolant, the temperature of the chip can be controlled and maintained at a steady level during the thermal cycling test. The thermal head consists of a thermal fin, a heat transfer plate, and the individual chip being thermal cycle tested. First, the coolant is passed through the thermal fin, which quickly lowers the temperature of the fin to the desired test temperature. Then, via conduction through the heat transfer plate, the temperature of the coolant indirectly drops the temperature of the chip, creating a thermal gradient that simulates the chip’s intended operating environment.

The use of thermal cycling tests and other types of semiconductor test equipment is critical for ensuring the reliability and performance of electronic devices and components. The results of the test can be used to improve the design of the chip, or to identify any potential issues that may need to be addressed during the manufacturing process. This is particularly important in industries like aerospace and defense, where electronic systems may be subjected to extreme temperatures and other harsh environmental conditions.