How is a C02 Digital Flow Meter Used in the Creation of Beer, Wine and Other Carbonated Drinks?

Carbonation is a concept you may be familiar with. You may not know this word, but to most of you, carbonation is evident almost every day; this is the process that creates bubbles in cola and mineral water. Flow meters play an instrumental role in this process. Carbon dioxide (CO2) is measured and controlled using the flow meter during carbonation for the carbonated drinks to dissolve in it.

We have provided many industry professionals with pneumatic devices, including mass flow controllers and digital flow meters for engineers in many diverse industries for their applications. These can be utilized in the carbonation process to greatly improve the results of the carbonation process for beverage producers.

What is the carbonation process?

A liquid is carbonated by absorbing carbon dioxide through a chemical process. According to Henry’s law, the following thermodynamic process occurs: when a gas is dissolved in a liquid, it exerts a pressure on the liquid. This pressure is proportional to the quantity of gas dissolved in the liquid.

Carbonation involves the addition of carbon dioxide to liquids in order to achieve a certain concentration of CO2. Depending on the type of product, pressure and temperature conditions need to be met in order to effectively manufacture it. It is crucial to maintain the right balance throughout the process, and this is where flow instruments such as the Kelly Pneumatics C02 Digital Flow Meter become useful.

The Carbonation Process

Several stages are involved in the production of carbonated beverages. Firstly, mix all the ingredients in an appropriate vessel, except for the ones noted below. In order to keep air, oxygen, and air ingress to a minimum, mixing must be controlled very carefully. This is to avoid vertexing or other operations that draw air into the mix. A carbonation process is carried out after the mix has been checked for quality parameters.

One of two basic methods is used to manufacture carbonated beverages. A premix system involves mixing all the necessary ingredients for the beverage, and then the total volume of the drink is chilled and carbonated. Afterward, if the product is to undergo flash pasteurization, it will be chilled and carbonated.

The alternative postmix system prepares concentrated syrup containing all the ingredients except for most of the water and carbon dioxide. A syrup of this type typically comprises 15% to 20% of the final volume and is frequently flash pasteurised before diluting.

By using separate cooling and carbonation, a proportioning system blends chilled and carbonated water in the required amounts. The carbonated water is then transmitted to the filler.

A carbonation process involves injecting the gas into a stream of water or product or adding it to a static liquid under high pressure.

What is the purpose of monitoring CO2 in a beverage plant?

In the beverage industry, most of the CO2 is produced through carbonating processes. In addition to that, CO2 is produced during fermentation and it is used for refrigeration – so in these types of facilities, CO2 is common.

A high concentration of CO2 in enclosed areas where workers attend to their jobs may pose a lethal risk. The effects of excessive CO2 are headaches, drowsiness, unconsciousness, and even death. Any CO2 level that exceeds 5000 parts per million is considered alarming. Its smell and appearance cannot be inferred from its gas. In order to maintain a high level of operational safety in soft-drink factories and breweries, CO2 control and alarm systems are recommended.

The Importance Of C02 Digital Flow Sensor In Carbonated Drink Manufacturing And Bottling Plants:

Bottling lines that fill carbonated drinks are often located in separate areas of a factory to ensure hygienic conditions and reduce the risk of CO2 incidents. When sparkling drinks are bottled or canned, there is a controlled loss of CO2. This is minimal but adds up considering that industrial lines are able to fill up to 30.000 bottles an hour. At each filling, a tiny amount of CO2 is released into the atmosphere.

In factories, gas cylinders are used to store and deliver large amounts of CO2. A thin crack may occur during storage or transport, allowing unnoticed gas to escape. As a result of fermentation, drinks that are not meant to be carbonated, such as beer and wine, release CO2. Controlling the flow of the gas is necessary. CO2 sensors help maintain the atmosphere and prevent leakage.

Using the Kelly Mass Flow Meter in the Carbonation Process

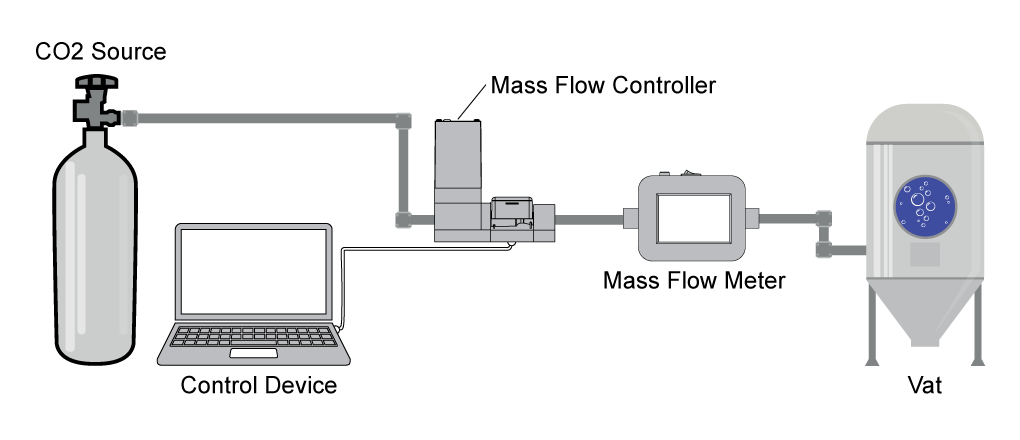

To accurately measure CO2 injection during the carbonation process, our Carbon Dioxide Mass Flow Meter can be used inline with the supply gas to measure CO2 flow rates. This allows for accurate reading of the current amount of CO2 injected into the liquid, represented in terms of either volumetric or mass flow.

Using the touch screen on the flow meter, the desired units of measurement can be selected easily. The gas flow meter also offers screen output of the current downstream CO2 pressure, atmospheric pressure, and temperature of the CO2 in the line. The flow meter also offers a 0–5-volt analog output voltage, that represents the current flow rate. This can be sampled by a monitoring system to accurately record the CO2 delivery rate per carbonation process.

The flow meter can also be paired with our Mass Flow Controller to accurately control the CO2 flow rate directly. Combining these two products are a perfect solution for beverage producers who want to both accurately control and monitor the CO2 used in their carbonation processes.

Using reliable CO2 monitoring systems is crucial for beverage manufacturers!