Gas Flow Control Systems Of An Anesthesia Machine

Anesthesia Machine General Overview

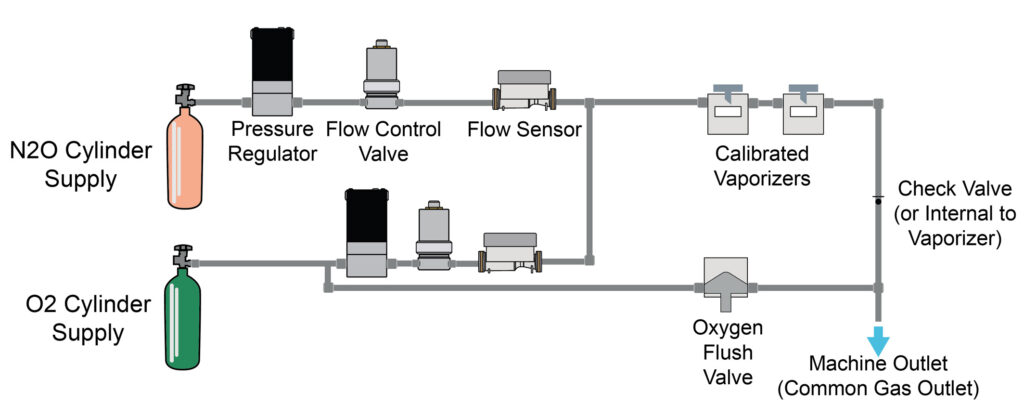

The anesthesia machine is a vital piece of equipment in any operating room. Its function is to deliver a controlled mix of gases to the patient, and it accomplishes this by regulating pressure and flow. The pressure regulator ensures that the gas pressure remains constant, while the flow meter controls the flow of gas. The proportional valve is used to maintain the oxygen concentration at a safe level, and the breathing tubes transport the gas mixture to the patient. In addition, the anesthesia machine also has several safety features, such as alarms that sound if the oxygen level drops below a certain level. The anesthesia machine is a complex piece of equipment, but it plays a vital role in ensuring that patients receive the care they need during surgery.

Rebreathing vs. Nonrebreathing Systems

Rebreathing:

Chemical absorbents are used to absorb carbon dioxide exhaled by rebreathing systems. After removing carbon dioxide, their exhaled gases flow back into the patient, thus they are termed rebreathing systems. Anesthetic, oxygen, heat, and moisture are conserved in rebreathing systems over nonrebreathing systems, but ventilation is more difficult. The cost of purchasing a rebreather compared to its operating cost is relatively high.

Non-Rebreathing:

Chemical absorbents for CO2 are not used in nonrebreathing systems, but rather the system relies on high flow rates of fresh gas to flush out exhaled CO2. The group of such systems is called Mapleson or non-rebreathing systems. Since some of these systems rebreathe exhaled gases, this terminology is technically incorrect. Its simple design allows it to be placed conveniently, is lightweight, compact, has few moving parts, is relatively inexpensive, imparts little resistance to respiration, does not require carbon dioxide absorbents, adds minimal mechanical dead space, and has a rapid adjustment of the inspired anesthetic concentration. Mapleson systems have a major disadvantage because their flow rates of fresh gas require higher flow rates, which decreases overall efficiency. Hypothermia, as well as drying of the respiratory tract, is also promoted by high flow rates.

Gas Flow Regulation of an Anesthesia Machine

An anesthesia machine is a complex piece of equipment that is used to deliver anesthesia to patients. The machine controls the pressure and flow of gases and monitors the patient’s vital signs. There are three main components that control gas flow: the pressure regulator, the flow meter, and the proportional valve. The pressure regulator is responsible for maintaining a constant pressure in the system. The pressure regulator is typically located at the point where gas enters the machine. The pressure regulator is controlled by a knob or lever, which can be adjusted to increase or decrease the pressure.

The flow meter is responsible for measuring the flow of gas through the system. The flow meter is typically located between the pressure regulator and the proportional valve. The flow meter is controlled by a knob or lever, which can be adjusted to increase or decrease the flow. The proportional valve is responsible for regulating the flow of oxygen into the system. The proportional valve is located between the pressure regulator and the patient’s connection point. The proportional valve is typically controlled by an internal control system, which can be adjusted to increase or decrease the oxygen content of the gas mixture.

Anesthesia machine components:

Gas Cylinder

Medical gases (ex., N2O) are stored in cylinders for use as oxygen sources and other medical gas sources. There are two main sizes of these oxygen cylinders: E and H. The E cylinder of oxygen holds approximately 700 liters, while the H cylinder holds approximately 7,000 liters. The pressure in both containers is 2,200 pounds per square inch (psi) when they are full. A cylinder of oxygen with a pressure of 1,100 psi holds about 350 liters; its volume is proportional to its pressure. The volume of a full E cylinder of N2O is equal to 1,600 liters, while the volume of a full H cylinder is equal to 16,000 liters. Nitrous oxide cylinders filled with H are under 750 psi at room temperature. Color-coding is used for the cylinders: oxygen is green, and nitrous oxide is blue.

Digital Gas Flow Meter

Anesthesia machines include a flow meter as part of their low-pressure systems. Measurement and indication of gas flow rate are possible through the flowmeter, which allows control of gas delivery to the vaporizer/common gas outlet with high precision. As much as a liter or milliliter of anesthesia gas can be pumped through a flow meter. Pressure gauges, regulators, and flow meters should be properly calibrated and used properly to avoid failures. It is recommended that flow meters be switched off when not in use, as opening the flow meter will cause pressure to build up in the glass tube and indicator quickly. In most cases, overtightening the valve causes flow meters to fail.

Pop-off valve

The pop-off valve is also a critical component of anesthesia machines, as it vents waste anesthetic gases to the scavenger system, which removes them from the environment. As a result of the pop-off valve, also called a pressure-limiting valve, relief valve, or overflow valve, excessive pressure is drained from the gas line to the scavenger system. Pop-off valves also enable rapid elimination of anesthetic gases from the circle when 100% oxygen is required. If the patient is spontaneously breathing, the pop-off valve should be open. If the patient is being ventilated manually or mechanically, it should be closed.

Oxygen Proportional Valve

Through the oxygen proportional valve, oxygen gas is passed through the vaporizer and delivered only to the common gas outlet and then to the breathing circuit. In addition to providing a high flow rate of oxygen, it delivers unmetered oxygen to the breathing circuit. It is estimated that this flow, between 30 and 50 L/min, can rapidly fill the respiratory system. In pediatric circles, over pressurizing the patient’s respiratory system should be avoided when the patient is connected to the breathing circuit using the flush valve. As soon as a patient is connected to the breathing circuit, increase the flow on the flow meter.

For this purpose, the Kelly Proportional Valve product line can greatly improve the accuracy of the oxygen delivered. With valves of varying sizes and flow capacities, the proportional valves can offer the required flow rates to the patient. For example, the smallest valve, the Miniature Proportional Valve can be utilized in pediatric anesthesia devices, due to its extremely accurate, low volume flow rates. Conversely, the High Flow Proportional Valve can deliver flow rates of over 300 SLPM, even at lower pressures (e.g. 1-2 PSIG).