Controlling Air Supply in Cooling Systems for Hydrogen Fuel Cells

A fuel cell is an electrochemical device that converts chemical energy from a fuel into electrical energy. Hydrogen is often used as fuel for fuel cells, and the most common type of fuel cell is the hydrogen fuel cell.

In order to work properly, fuel cells must be cooler than the operating temperature of the electrolyte, typically around 80°C. If the fuel cell gets too hot, the electrolyte will begin to decompose, and the reaction will become less efficient. For this reason, cooling systems are essential for the proper operation of fuel cells.

There are two main types of cooling systems used for fuel cells: forced convection and free convection. Forced convection systems use pumps or fans to circulate coolant through the fuel cell, while free convection systems rely on natural convection currents to move the coolant.

Condensers are often used in forced convection systems to help remove heat from the coolant before it is circulated back through the fuel cell. This helps to improve the efficiency of the system and prevent the coolant from becoming too hot.

Free convection systems are simpler and often more reliable than forced convection systems, but they are not as efficient at heat removal. For this reason, they are typically only used in small fuel cells or in applications where space is limited.

Hydrogen fuel cells are very efficient at converting chemical energy into electrical energy, and they are also emissions-free. This makes them an attractive option for electronic vehicle manufacturers who are looking to meet increasingly stringent emissions standards.

The cooling system is responsible for keeping the fuel cell operating at the correct temperature. One of the most important parts of the cooling system is the air supply. The air supply must be carefully controlled in order to ensure that the fuel cell is cooled properly. If the air supply is not controlled properly, the fuel cell can overheat and malfunction.

Intake systems play a crucial role in controlling the air supply to a fuel cell. The intake system must be designed to allow the correct amount of air to enter the fuel cell. The intake system must also be designed to maintain a pressure differential between the inside and outside of the fuel cell.

The mass flow rate of the intake air must be carefully controlled in order to maintain the correct amount of cooling. The intake air must also be filtered to remove any contaminants that could damage the fuel cell.

The pressure differential is created by the difference in pressure between the inside and outside of the fuel cell. The pressure differential must be maintained in order to ensure that the fuel cell operates correctly. The intake air must be cooled before it enters the fuel cell. The intake air must also be humidified to prevent the fuel cell from drying out.

It is important to control the intake airflow to a fuel cell in order to ensure that the fuel cell functions properly. If the intake airflow is not controlled properly, the fuel cell can overheat and malfunction.

Hydrogen fuel cells offer a number of advantages over other types of power sources, including lower emissions and the ability to generate electricity using only water as a by-product. However, one potential drawback of fuel cells is their sensitivity to changes in temperature. In order to maintain optimal performance, fuel cells must be kept within a narrow range of temperatures using a cooling system.

The most common type of cooling system used for fuel cells is air-cooled, which supplies cooled air to the fuel cell stack in order to keep it at the proper operating temperature. While this type of system is typically less expensive than water-cooled systems, it can be less effective in hot weather conditions. In order to maintain proper cooling, the air supply must be controlled carefully to avoid over-cooling or under-cooling the fuel cells.

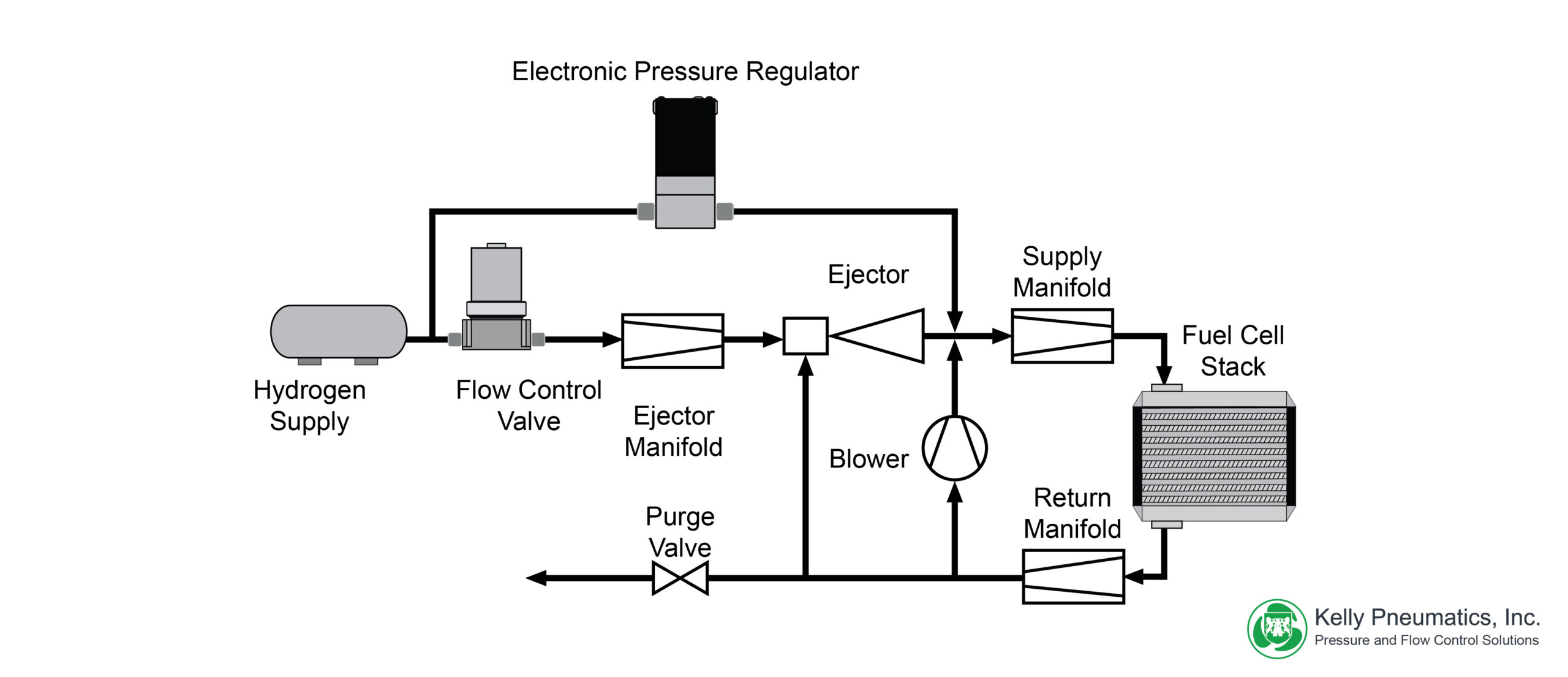

One method of controlling the air supply is to use a variable speed blower, which can adjust the flow of air based on the current temperature. This allows the system to maintain a more consistent temperature, even in hot weather conditions.

Another method is to use an air recirculation system, which recycles a portion of the cooled air back into the fuel cell stack. This can help to reduce the overall amount of energy required to keep the fuel cells at the proper operating temperature. either method, it is important to have a well-designed cooling system in order to avoid any potential damage to the fuel cells.

Hydrogen fuel cells offer several advantages over other types of power sources, but their sensitive nature means that care must be taken to maintain them within the proper operating temperature range. An air-cooled cooling system can be an effective way to keep fuel cells at the optimum temperature, but it is important to carefully control the air supply in order to avoid over-cooling or under-cooling the cells. By using a variable speed blower or an air recirculation system, you can help to ensure that your fuel cells remain at the ideal temperature, even in hot weather conditions.