C02 Injection In The Carbonated Beverage Manufacturing Process

Carbonated beverages have been a staple in our daily lives for decades. We have all enjoyed a refreshing soda, beer, or sparkling water, but have you ever wondered how that bubbly goodness is created? One of the essential steps in the carbonated beverage production process is injecting CO2 into the liquid. In this blog post, we will explore the process of CO2 injection in the production of carbonated beverages and how using products from Kelly Pneumatics can help you attain precise CO2 injection.

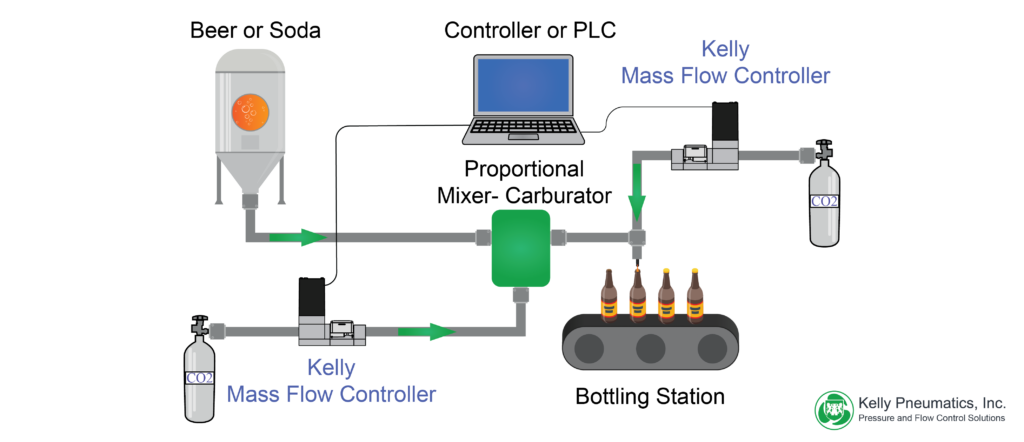

The CO2 injection process involves dissolving carbon dioxide gas into a liquid to create the effervescence we all love. There are two primary methods of CO2 injection: carbonation under pressure and carbonation with the aid of a carbonator. Carbonation under pressure involves pumping CO2 into a sealed container of liquid, while carbonation with the aid of a carbonator involves using a device that allows CO2 to dissolve into the liquid as it flows through. To ensure the right amount of CO2 is injected into the liquid, precise measurements and controls are required. This is where Kelly Pneumatics comes in. They offer a range of products designed to improve the CO2 injection process, such as proportional valves, regulators, and flow controllers. These products are engineered to provide accurate, consistent, and reliable results for the carbonated beverage production process.

One of the key products from Kelly Pneumatics for CO2 injection is their Proportional Valve. This valve offers precise control over the flow of CO2, allowing for a consistent level of carbonation throughout the beverage production process. The proportional valve uses feedback control to adjust the flow rate of CO2 to maintain a constant CO2 level. This ensures that the beverage has the perfect level of carbonation, enhancing its flavor and mouthfeel.

Another product that can aid in CO2 injection is Kelly Pneumatics’ Electronic Pressure Regulator. This regulator provides precise pressure control, ensuring that the CO2 pressure is maintained at the desired level. By maintaining a consistent pressure, the CO2 is dissolved into the liquid at a consistent rate, resulting in a uniform level of carbonation throughout the beverage. This precision is particularly important in high-volume production environments, where maintaining consistent quality is critical.

Kelly Pneumatics’ Mass Flow Controllers are another essential tool in the CO2 injection process. These controllers allow for precise control of the liquid flow rate, ensuring that the CO2 is injected at the right rate. By controlling the flow rate of the liquid, the CO2 is dissolved into the liquid more effectively, resulting in a consistent level of carbonation throughout the beverage.

CO2 injection is a critical step in the production of carbonated beverages. The use of precise control mechanisms is essential to achieving consistent results and maintaining the highest quality standards. Kelly Pneumatics offers a range of products designed to aid in the CO2 injection process, including proportional valves, Electronic Pressure Regulator, and Mass Flow Controllers. These products are engineered to provide accurate, consistent, and reliable results, ensuring that your carbonated beverages meet the highest quality standards. So, if you are looking for precision and efficiency in your CO2 injection process, look no further than Kelly Pneumatics.

Kelly Pneumatics has been a leader in the pneumatic industry for over three decades, providing high-quality products and exceptional customer service to customers worldwide. Their commitment to precision and reliability has earned them a reputation as a trusted supplier of precision pneumatic products, including those designed for the carbonated beverage production process.

At Kelly Pneumatics, they understand the importance of precision in the beverage production process. That’s why they offer a range of products that are designed to provide accurate and consistent results, ensuring that your carbonated beverages meet the highest quality standards. Their products are engineered to provide precise control over the CO2 injection process, resulting in beverages with the perfect level of carbonation. In addition to their precision products, Kelly Pneumatics is committed to providing exceptional customer service. Their team of experts is available to help you select the right products for your specific application and provide technical support to ensure that your CO2 injection process runs smoothly.

In conclusion, CO2 injection is a critical step in the production of carbonated beverages. Achieving precise and consistent results is essential to maintaining the highest quality standards. Kelly Pneumatics offers a range of products designed to aid in the CO2 injection process, including proportional valves, Electronic Pressure Regulators, and Mass Flow Controllers. Their products are engineered to provide accurate, consistent, and reliable results, ensuring that your carbonated beverages meet the highest quality standards. With Kelly Pneumatics’ precision products and exceptional customer service, you can be confident that your CO2 injection process will run smoothly and efficiently, resulting in delicious carbonated beverages.