Traditional electronic pressure regulators typically employ a dual on/off valve design, with both an inlet and exhaust valve. Changes in pressure are controlled by cycling the on/off valves to open and close via Pulse Width Modulation. Using Pulse Width Modulation can be problematic for control systems for various reasons. Problems associated with using pulse width modulation of on/off valves and frequent valve cycling include a much shorter product life, product noise, control circuitry dead-band, pressure oscillation, and inconsistent performance during dynamic output conditions.

Some pressure regulators incorporate an inlet proportional valve to compensate for these performance issues. However, these units typically use a single on/off solenoid exhaust valve to vent excess pressure and compensate for changing flow rates to the system. Typically, this is achieved with rapid valve cycling, so applications with dynamic output pressure rates are more susceptible to oscillation, as the exhaust valve must continually cycle at a rapid hertz to compensate for the dynamic pressure changes.

A Superior Design

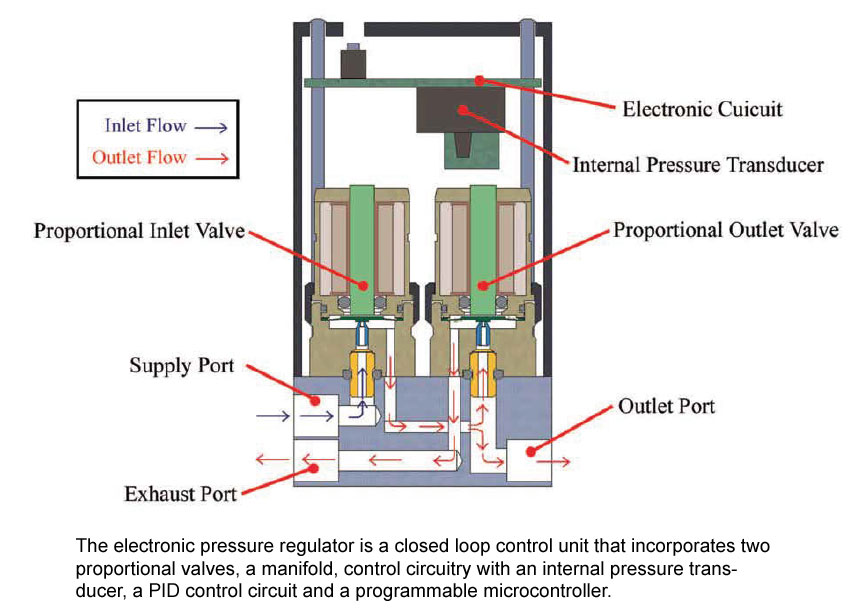

The critical component of the Kelly Pneumatics electronic pressure regulators is the dual proportional valve design. One valve controls the inlet and the other the exhaust; each valve proportionally increases or decreases the output pressure, respectively.

Why Use Proportional Valves?

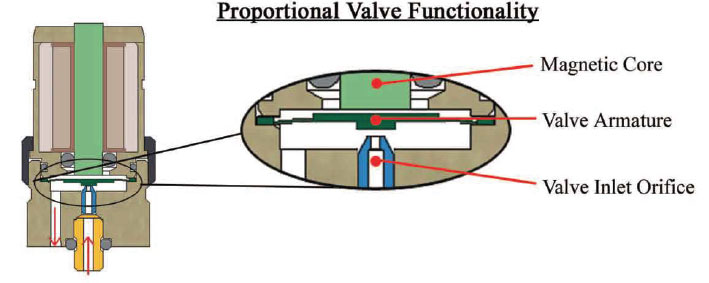

The incorporation of two proportional valves avoids many problems associated with traditional on/off valve regulators. This is mostly due to the inherent design of the proportional valves that control pressure regulation. Each proportional valve uses a single armature design, which offers virtually frictionless performance. Outlet pressure/flow is acquired by proportionally moving the single valve armature away from the valve inlet orifice. The total travel distance of the valve armature is only thousands of an inch. A slight increase or decrease in the armature distance from the valve orifice will result in variable outlet flow rates and pressures.

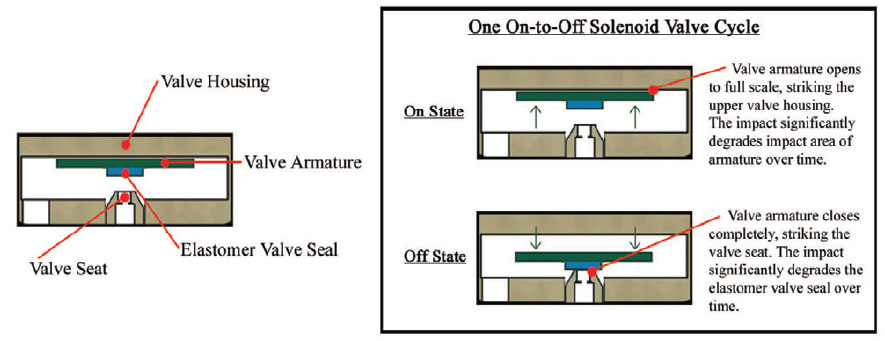

Conversely, on/off valves do not typically over variable flow rates and use an armature with a single, calibrated travel distance – the valve armature during “off” states is completely closed against the valve seat, while during “on” states is completely opened against the valve housing.

On/off valves cycling can be can be problematic when considering the aforementioned use of pulse width modulation in other pressure control units that must cycle valves at a particular hertz, which can substantially lessen the life of the solenoid valves being cycled and subsequently the product itself. This is especially true of applications with consistent outlet flow and/or frequently changing output pressures to the system when valve cycling is more consistent. Therefore, in many applications, valve cycling can be constant for these products, severely limiting product life. In contrast, our electronic pressure regulator design ensures greater product life: during use, the internal proportional valves need only change their respective armature distance to change the output pressure and flow of the pressure controller. For example, when an increase of flow occurs downstream, the inlet proportional valve is immediately adjusted to compensate by slightly adjusting the internal valve armature distance in a single movement. Additionally, during steady states, the proportional valves maintain the valve armature distance, with no wear to the valves themselves.

Don’t Compromise Performance

When designing and building high-precision scientific, laboratory or analysis equipment, it’s essential that pressure is controlled exactly as the process demands. The Electronic Pressure Regulators incorporate our patented technology and years of experience to deliver the performance you need.