Optimizing Hydrogen Generation: An In-Depth Look at Electrolysis & Kelly Pneumatics’ Comprehensive Solutions

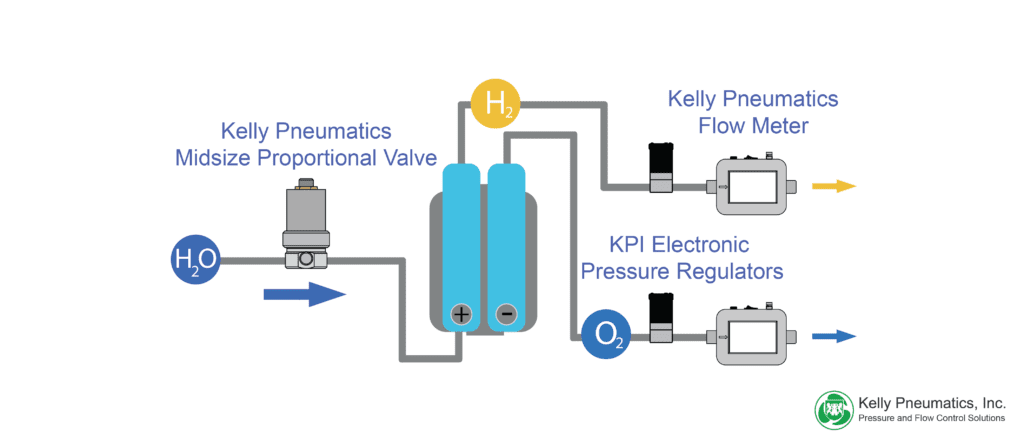

Electrolysis, a process that converts electrical energy into chemical energy, is increasingly becoming the cornerstone of hydrogen production. In the pursuit of this technological advancement, kellypneumatics.com is proud to feature state-of-the-art products that play integral roles in Hydrogen Generation and Electrolyzer system testing and regulation. This blog post takes a deep dive into the process of electrolysis and examines the utility of the Kelly Pneumatic Midsize Proportional Valve, Digital Mass Flow Meter, and Electronic Pressure Regulator.

Electrolysis and Hydrogen Generation

The process of electrolysis involves breaking down compounds by passing an electric current through them. When applied to water, hydrogen gas is produced at the cathode and oxygen at the anode. This method of hydrogen generation is increasingly preferred for its environmental friendliness and its ability to use renewable energy sources.

The Integral Components of Hydrogen Generation

Harnessing the process of electrolysis to generate hydrogen in a controlled, efficient manner requires reliable, high-performance components. At Kelly Pneumatics, we offer a suite of products that optimize this process by ensuring precision, accuracy, and stability.

Kelly Pneumatic Midsize Proportional Valve

The Kelly Pneumatic Midsize Proportional Valve is the heart of electrolysis operations. It provides precise control of gas flow, ensuring a balanced and efficient electrolysis process. Its design allows for quick response times and consistent performance, making it an indispensable part of hydrogen generation.

Digital Mass Flow Meter

The Digital Mass Flow Meter is a critical component in an Electrolyzer system. By accurately measuring the mass flow rate, it facilitates precise control of the hydrogen and oxygen produced during electrolysis. This real-time data is vital to optimize the process, increase yield, and reduce energy consumption.

Electronic Pressure Regulator

Finally, the Electronic Pressure Regulator offers the essential function of managing system pressure. It ensures the safe operation of the electrolysis process by maintaining a stable pressure environment. With its capability to provide fast, accurate, and reliable pressure control, it is an invaluable tool in hydrogen generation.

The Synergy of Components

When these components are used together in an Electrolyzer system, they form an impressive synergy. The Kelly Pneumatic Midsize Proportional Valve, with its precise gas flow control, compliments the Digital Mass Flow Meter’s ability to measure mass flow rate accurately. The Electronic Pressure Regulator ties it all together by maintaining a stable pressure environment, ensuring the safety and efficiency of the system.

These high-quality components from Kelly Pneumatics, available for purchase on our website, are ideal for anyone looking to venture into the promising world of hydrogen generation. They offer unparalleled reliability, accuracy, and control in the electrolysis process.

Closing Thoughts

Electrolysis holds immense potential in the drive towards a sustainable, hydrogen-based economy. With Kelly Pneumatics’ innovative and reliable products, mastering this complex process becomes significantly more achievable.

Our mission at Kelly Pneumatics is to provide solutions that help harness the power of electrolysis for hydrogen generation effectively. Our product range is designed to provide the precision, control, and reliability required for this process. The Midsize Proportional Valve, Digital Mass Flow Meter, and Electronic Pressure Regulator are exemplary manifestations of this commitment.

Investing in the right tools for electrolysis and hydrogen generation is more than just purchasing products. It’s about participating in a sustainable future and harnessing the potential of technology to address some of our most significant challenges. We invite you to join us in this journey and explore our product range on kellypneumatics.com.