Mass Flow Controllers used in PEM Fuel Cell Testing

Introduction

PEM (Proton Exchange Membrane) fuel cells have gained significant attention as a clean, efficient, and reliable energy source for various applications, including automotive, stationary power, and portable power solutions. As these fuel cells continue to evolve, the need for precise and accurate testing procedures becomes increasingly important. In this blog post, we will explore the role of mass flow controllers in PEM fuel cell testing, with a focus on the innovative solutions offered by Kelly Pneumatics. We will also discuss the importance of regulating oxidant and reactant ratios and distributions across gas diffusion layers of stacks, as well as how the use of Kelly Pneumatics Mass Flow Controllers ensures superior, reliable, and fast response times in this crucial process.

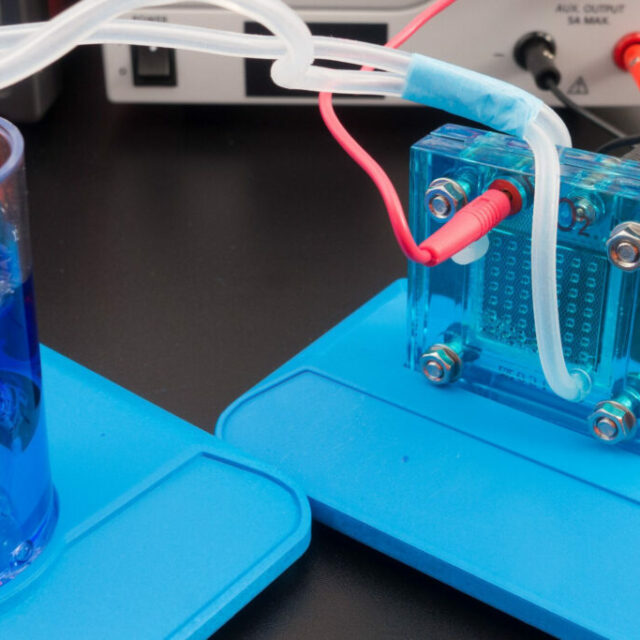

PEM Fuel Cell Testing Procedure

During PEM fuel cell testing, it is essential to simulate real-world operating conditions to accurately measure performance, durability, and efficiency. This process involves providing the fuel cell with the appropriate mixtures of hydrogen and air (or oxygen) at specific flow rates, pressures, and temperatures. The precise control of these parameters is critical in achieving optimal performance, as it ensures that the appropriate amount of reactants and oxidants are available for the electrochemical reactions taking place within the fuel cell.

Importance of Regulating Oxidant and Reactant Ratios and Distributions

To maximize the efficiency and performance of a PEM fuel cell, it is vital to maintain an optimal balance between the hydrogen (reactant) and air or oxygen (oxidant) supplied to the fuel cell stack. This balance is achieved by regulating the flow rates and pressures of the gases, which in turn affects the distribution of these gases across the gas diffusion layers within the fuel cell stack. An uneven distribution of gases can lead to localized areas of insufficient reactants or oxidants, resulting in decreased performance, lower efficiency, and potential damage to the fuel cell components.

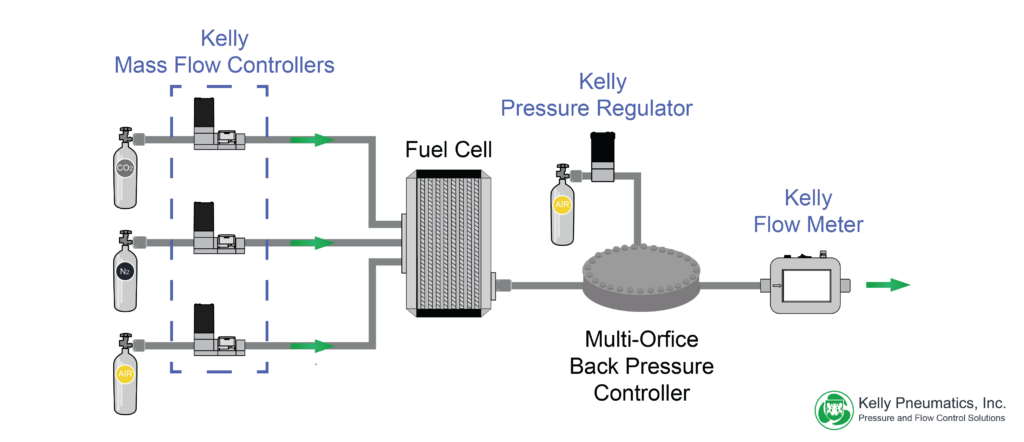

Kelly Pneumatics Mass Flow Controllers: A Superior and Reliable Solution

The utilization of Kelly Pneumatics Mass Flow Controllers in PEM fuel cell testing provides an advanced, reliable, and fast-responding solution for the flow regulation required in this procedure. These mass flow controllers offer precise control over the flow rates and pressures of the reactant and oxidant gases, ensuring an optimal balance between these critical components. With their high accuracy, repeatability, and rapid response times, Kelly Pneumatics Mass Flow Controllers are an ideal choice for PEM fuel cell testing applications.

Complementary Solutions from Kelly Pneumatics: Electronic Pressure Regulators

In addition to their innovative mass flow controllers, Kelly Pneumatics also offers Electronic Pressure Regulators that complement the flow regulation process during PEM fuel cell testing. These pressure regulators provide precise control over the inlet and outlet pressures of the gases being supplied to the fuel cell stack, ensuring a stable and consistent pressure environment. By maintaining the correct pressures, Electronic Pressure Regulators help to optimize the distribution of reactants and oxidants across the gas diffusion layers, further enhancing the performance and efficiency of the fuel cell.

Conclusion: Endorsing Kelly Pneumatics Products for PEM Fuel Cell Testing

In conclusion, the use of Kelly Pneumatics Mass Flow Controllers and Electronic Pressure Regulators in PEM fuel cell testing offers numerous benefits. These advanced, reliable, and fast-responding solutions ensure precise control over the flow rates and pressures of the reactant and oxidant gases, resulting in optimal performance, efficiency, and durability of the fuel cell. By utilizing these innovative products from Kelly Pneumatics, researchers and engineers can be confident in the accuracy and reliability of their fuel cell testing procedures, ultimately contributing to the continued development and advancement of this promising clean energy technology.