Implementing Electronic Pressure Regulators in Semiconductor Wafer Dicing

Wafer Dicing

Semiconductor wafer dicing, is a key process in the fabrication of semiconductor devices. It is the stage in which individual semiconductor chips are precisely cut from a silicon wafer, preparing them for eventual assembly into products that power our digital world. As demand for high-performance and miniaturized devices continues to grow, the importance of precision in wafer cutting cannot be understated.

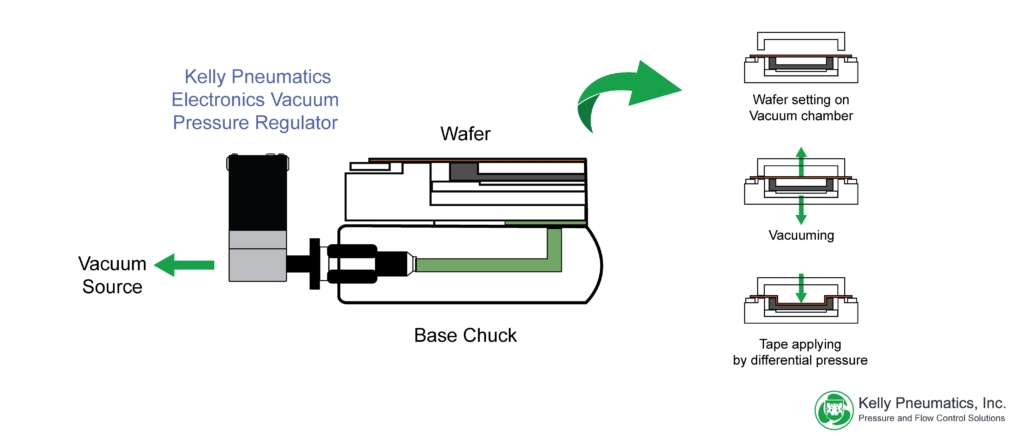

This precision is predicated on the utilization of vacuum pressure, crucial for enabling the exact type of cut necessary for the wafer chuck feature. The wafer chuck is a critical component in many semiconductor manufacturing processes as it holds the wafer in place during the cutting process. For this, an even and stable vacuum pressure is necessary to prevent any shift or movement of the wafer, ensuring the precision of the cutting process.

Enter electronic pressure regulators (EPRs). These devices play a vital role in maintaining this necessary vacuum pressure, and thus are central to the precision and reliability of wafer dicing.

Understanding the Role of Electronic Pressure Regulators

An EPR is a device that controls the pressure of a fluid in a system, in this case, the vacuum pressure for the wafer chuck. By maintaining a constant vacuum pressure, the wafer is held securely during the cutting process. This stability is essential for achieving clean, precise cuts on the wafer without the risk of damaging the valuable material.

However, not all EPRs are created equal. Different models and brands offer varying degrees of precision and reliability. For the exacting requirements of semiconductor wafer cutting, a high-quality, reliable EPR is indispensable.

The Kelly Pneumatics Advantage

When it comes to reliable and accurate pressure control, Kelly Pneumatics Electronic Pressure Regulators stand out in the industry. Renowned for their reliability and precision, they offer a distinct advantage in the semiconductor wafer cutting process.

Kelly Pneumatics EPRs are designed to offer superior stability. With their state-of-the-art closed-loop control, these regulators maintain consistent pressure even under changing conditions. This ensures that the vacuum pressure on the wafer chuck remains steady throughout the cutting process, allowing for high-precision cuts every time.

Moreover, Kelly Pneumatics EPRs are known for their robustness and durability. In an industry where downtime can lead to significant losses, the reliability of Kelly Pneumatics EPRs minimizes the risk of system failure. This translates into less maintenance, longer equipment life, and more efficient operation of the cutting process.

Finally, the user-friendly design of Kelly Pneumatics EPRs makes them an excellent choice for technicians and engineers in the semiconductor industry. With easy-to-use controls and clear feedback mechanisms, these regulators are designed for seamless integration into existing systems, allowing for improved operational efficiency.

Conclusion

In the high-stakes world of semiconductor manufacturing, the precision of wafer cutting is paramount. Implementing Electronic Pressure Regulators in this process provides an enhanced level of control, leading to superior precision and reliability. The Kelly Pneumatics Electronic Pressure Regulator is a prime choice in this field, offering consistent, reliable performance to meet the exacting standards of semiconductor wafer cutting. The result? A precision-cut wafer, ready for the next stage in the journey of powering our digital world.