Semiconductor Thermal Cycling

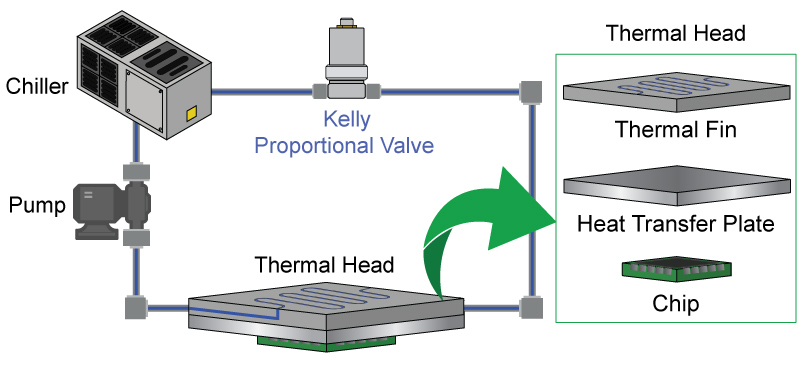

When completing Thermal Cycle Tests, HFE or Glycol coolant is processed by a pump and chiller upstream from the Kelly Proportional Valve. The pump is used to circulate the coolant through the system, while the chiller is used to maintain the temperature of the coolant. This ensures that the Kelly Proportional Valve is supplied with enough pressure to continue flowing and that the Glycol remains at the correct temperature throughout the test.

The Kelly Proportional valve is used to control the flow of the HFE coolant through the thermal head, allowing for precise control of the thermal gradient and ensuring that the chip is subjected to the correct thermal stress. By adjusting the flow rate of the HFE coolant, the temperature of the chip can be controlled and maintained at a steady level during the thermal cycling test. The thermal head consists of a thermal fin, a heat transfer plate, and the individual chip being thermal cycle tested. First, the coolant is passed through the thermal fin, which quickly lowers the temperature of the fin to the desired test temperature. Then, via conduction through the heat transfer plate, the temperature of the coolant indirectly drops the temperature of the chip, creating a thermal gradient that simulates the chip’s intended operating environment.

Using Kelly Proportional Valves for Thermal Cycling

The Midsize Proportional Valve can process Thermal Cycling precisely at temperatures as low as -60 C. When higher liquid flow rates are required, this valve can be used individually or in multiples on a manifold to control coolant flow proportionally.

For Thermal Cycling applications that require lower flow rates and quicker response times, the Miniature Proportional Valve is a perfect fit. It can be overdriven to have response times of less than 1 millisecond and is compact and light-weight.