Considerations When Choosing a Proportional Valve

In the medical device industry, there is an increasing demand for sleeker, smaller designs and speed to the marketplace with the latest and greatest products. Engineers tasked with designing and creating respiratory equipment such as ventilators and anesthesia machines have a host of critical challenges in front of them. End-users demand top performance and compliance with ever-changing regulatory standards. Original equipment manufacturers (OEM) have to meet these challenges by making machines that meet design and performance expectations while also keeping costs down. To do this, source parts and materials must meet the needs and help expedite the design process.

A direct proportional flow valve provides precision control for the flow of gas within these machines. They are integral to the design of a ventilator and inspiratory flow system.

Valve Functions

In any given machine, there can be up to a dozen proportional control valves. They usually reside in the middle of the system somewhere and provide flow control of the gasses and prevent the over-pressurization of the lines. The valves and many other components within the machine are safety and control elements because they keep the gasses flowing at the desired level.

Considerations When Choosing a Proportional Valve

When choosing a control valve, use the design and application specifications. These are general guidelines and by no means follow a one-size-fits-all solution. The designer of said machine knows what will work best for the specific application. This is merely a guide.

Compliance

It’s important to select a valve that meets the most recent guidelines, laws, rules, and regulations relating to the manufacturing of medical devices. The rules are constantly changing to improve the equipment, so make sure the valve you select meets all the standards.

Air Source

Most operating room and emergency room ventilators use hospital supplied, plumbed air that is prone to significant fluctuations in air pressure. A proportional valve will control these fluctuations and keep the airflow balanced. Depending on the specific application, a high-pressure proportional valve can eliminate the need for a pressure reducing regulator.

We offer valves that accurately control flow in ventilator applications, which require high flow rates of oxygen and air with relatively low supply pressures. Our High Flow Proportional Valve can meet this high flow requirement using pressures supplied by plumbed air in hospital lines, which need to be regulated to a lower pressure to maintain stability in the pressure supply to the ventilator. Our High Flow Proportional Valve can deliver flow rates of over 300 liters per minute with a supply pressure below 2 PSIG.

Hysteresis

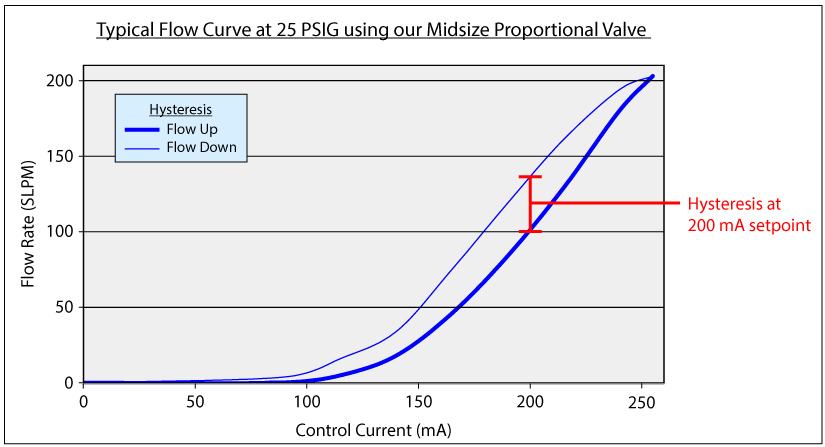

A vital consideration with any proportional valve design is hysteresis, a varying of flow at any given setpoint when increasing or decreasing flow. An example of a typical flow curve with hysteresis is shown below.

This variance in flow at a given setpoint due to hysteresis can cause control problems for applications requiring accurate flow control. Our valves offer very low hysteresis, with percentages as low as 2% (of full scale). Our Low Hysteresis Proportional Valve is a perfect fit for systems that require low hysteresis.

Device Size

The trend in machines of any kind, not just medical devices, is to make them smaller. Smaller systems are in demand, and employing a proportional valve with pressure regulation can reduce the number of components needed within the machine to control the flow. Fewer components in the machine mean the machine itself can be smaller.

Kelly Pneumatics offers small, lightweight proportional valves which deliver relatively high flow rates. In particular, our High Flow Miniature Proportional Valve can supply over 100 standard liters per minute (SLPM) of gas flow and only weighs a quarter of a pound.

Gas Compatibility

A certain calibration is necessary for each valve to accommodate a specific kind of gas. Careful selection of control valves with compatible elastomers is important when dealing with anesthesia applications. Our valves come standard with three elastomer types: Viton, EPDM, and Buna-N, but we can customize the elastomers to meet the most demanding applications. The valve material itself can also be modified to other metals – such as stainless steel – to handle even corrosive gases and liquids.