Understanding the Fundamentals of Mass Flow Technology

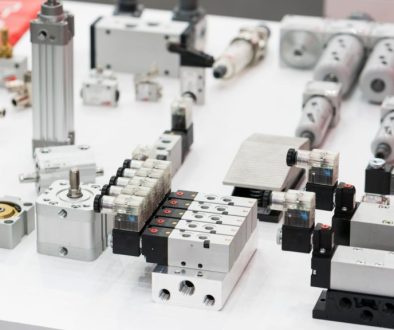

In the realm of fluid dynamics and gas management, the concept of Mass Flow Control stands out as a cornerstone. It represents the precise management and measurement of the rate of flow of gases or liquids in a system. This concept is invaluable in industries ranging from semiconductor manufacturing to pharmaceuticals, and biotechnology to aerospace. And as the demand for accurate, consistent, and reliable flow control grows, understanding the core of mass flow technology becomes indispensable. In this article, we’ll dive into the heart of mass flow control, explore its basic parameters, and shed light on the functioning of mass flow controllers and meters. By the end, you’ll not only have a deeper understanding of this pivotal technology but also know why Kelly Pneumatics Mass Flow Controllers stand out in the crowd.

Basic Parameters of Mass Flow

At its essence, mass flow is a measure of the amount of mass passing through a given point in a system per unit of time. It is generally represented in units such as grams per minute (g/min) or kilograms per hour (kg/hr). Two key parameters play a pivotal role in this realm:

Density: Density refers to the mass per unit volume of a substance. Different gases and liquids have varied densities, and changes in temperature or pressure can influence this.

Velocity: This is the speed at which the fluid or gas is moving. It is often a function of the pressure difference driving the flow and the resistance encountered.

These parameters, when accurately measured and controlled, can drastically affect the efficiency and accuracy of various processes where flow control is critical.

Mass Flow Controllers and Mass Flow Meters: How Do They Function?

These two instruments are central to the application of mass flow technology. While they might sound similar, they serve distinct purposes.

Mass Flow Meters (MFMs): These are devices designed to measure the mass flow rate of a fluid or gas. They don’t control the flow but provide a real-time reading. Different technologies, including thermal dispersion and Coriolis effect, are employed in MFMs to measure the flow. The reading from the MFM can then be used to manually or automatically adjust the flow.

Mass Flow Controllers (MFCs): Going a step further, MFCs not only measure but also control the flow of gas or liquid to a predetermined set point. They typically incorporate a mass flow meter, a control valve, and a controller. When the MFM in the MFC detects a difference between the actual flow rate and the desired set point, it sends a signal to the control valve to adjust the flow accordingly.

The Utility of Kelly Pneumatics Mass Flow Controllers and Their Applications

In the vast landscape of mass flow controllers, Kelly Pneumatics stands as a beacon of precision, reliability, and innovation. But what makes these controllers particularly exceptional?

Precision: Kelly Pneumatics Mass Flow Controllers are crafted with precision at the forefront. This ensures that flow rates are maintained consistently, leading to improved process outcomes.

Reliability: Built with high-quality materials and cutting-edge technology, these MFCs guarantee long-term performance without frequent maintenance or recalibration.

Versatility: Catering to a wide range of industries, from medical to manufacturing, these controllers can handle a diverse range of gases and flow rates, making them suitable for myriad applications.

Applications:

Semiconductor Manufacturing: Precise gas flow is essential for processes such as chemical vapor deposition.

Biotechnology: For cultivating cells in bioreactors, maintaining exact gas flow rates is crucial.

Research & Development: In laboratories, ensuring accurate flow helps in replicating experiments and getting consistent results.

Pharmaceuticals: From drug manufacturing to quality control, precise flow control ensures product consistency and safety.

Mastering the intricacies of mass flow technology is essential in today’s world, where precision, efficiency, and reliability are not just desired but demanded. As you embark on your journey to secure top-notch flow control solutions, let Kelly Pneumatics be your partner in success. With a track record of excellence and a suite of products tailored for diverse needs, you’re not just getting a product; you’re investing in peace of mind. Ready to elevate your flow control game? Explore the Kelly Pneumatics Mass Flow Controllers today and experience unparalleled precision and reliability. Your future in flow control starts here.