Understanding Mass Flow Rate

Mass flow rate is a critical parameter in various industries, from aerospace to pharmaceuticals. Its accurate calculation and control are essential for ensuring efficiency and quality in numerous processes. Kelly Pneumatics Inc. stands at the forefront of providing solutions that precisely manage this vital measurement.

What is Mass Flow Rate?

Mass flow rate is the measurement of the amount of mass passing through a point in a system per unit of time. It is commonly measured in kilograms per second (kg/s) or pounds per second (lbs/s) and is fundamental in determining the efficiency of a process.

Calculating Mass Flow Rate

The calculation of mass flow rate involves measuring the mass of a substance passing through a cross-sectional area per time unit. The basic formula is Mass Flow Rate=MassTime. Accurate measurement is crucial as even slight deviations can lead to significant efficiency losses or quality issues in production.

Importance in Commercial and Industrial Applications

In the commercial and industrial realms, the precision of mass flow rate calculation can directly impact the bottom line. For instance, in the manufacturing sector, the rate at which materials are used affects production speed and waste reduction. Similarly, in the pharmaceutical industry, the accurate delivery of gases or liquids during production ensures product consistency and safety. Manufacturing Process – Consider a company producing composite materials. Accurate control of resin and hardener flow rates is essential to maintain product integrity. An imbalance can lead to product failures, resulting in costly recalls and reputation damage. Pharmaceutical Application – In pharmaceutical manufacturing, the precision in the flow rate of active ingredients is crucial. An error in measurement could lead to ineffective or even harmful drug compositions.

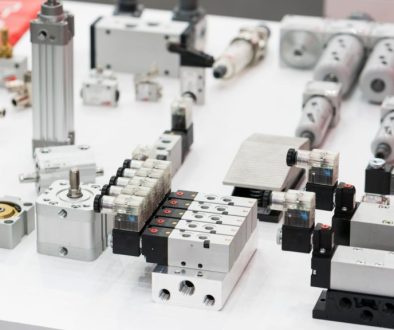

Kelly Pneumatics Mass Flow Controller

Enter the Kelly Pneumatics Mass Flow Controller – a state-of-the-art solution for precise mass flow rate measurement and control. This advanced system offers unparalleled accuracy, ensuring that the flow of materials is consistently maintained at the desired rate, thereby enhancing process efficiency and product quality.

Benefits in Real-World Applications

In our manufacturing scenario, the Kelly Pneumatics Mass Flow Controller ensures the exact mix of materials, minimizing waste and ensuring product consistency. In the pharmaceutical example, it guarantees the precise dosage of ingredients, upholding the highest safety standards. These benefits translate into cost savings, improved product quality, and enhanced customer satisfaction.

The calculation of mass flow rate is more than a technical necessity; it is a cornerstone of quality and efficiency in various industrial processes. With the Kelly Pneumatics Mass Flow Controller, businesses can achieve a new level of precision and reliability in their operations. We invite you to explore how our solutions can enhance your processes and drive your success. Contact Kelly Pneumatics Inc. today to learn more and take the first step towards optimized efficiency and quality in your operations.

For more information on optimizing industrial processes with advanced mass flow controllers, visit Kelly Pneumatics. Additionally, explore industry insights and applications at Control Global and Flow Control Network.