Advantages of Microfluidic Systems

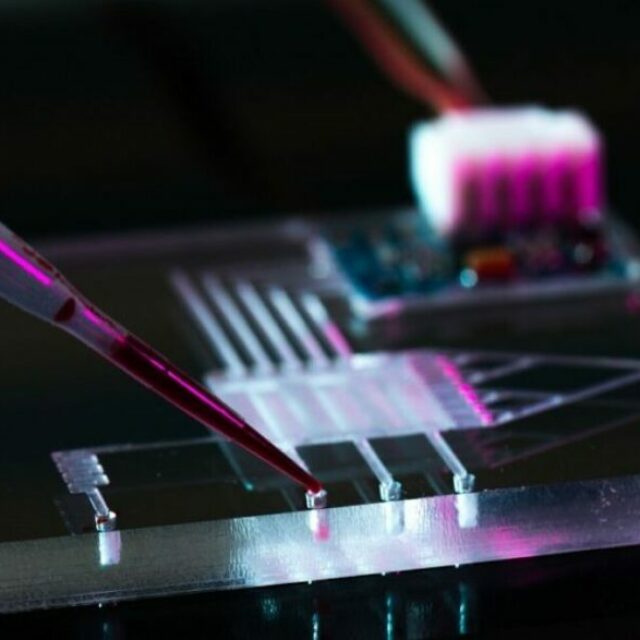

Microfluidic systems are nonturbulent, highly miniaturized devices that contain networks of microchannels for fluids to pass through or be contained in. The properties and behavior of the microliter quantities of fluids—which are often much different compared to fluids on a macroscale—are then monitored. Microfluidic systems are generally used in controlled biological experiments to facilitate operations that would normally require an entire laboratory in a simple microscopic system. Typically, microfluidic systems are just a few hundred microns in size. Such devices have a vast variety of applications in many research areas and numerous benefits. To learn about some of the main advantages of microfluidic systems, continue reading.

Cost savings

Reagents and samples used in biological analysis are often very costly. However, because microfluidic systems are so small, they consume minimal quantities of these items. As such, utilizing a microfluidic system can yield significant cost savings by reducing the amount of reagents and samples required for an experiment.

Increased precision

Another advantage of microfluidic systems is the increased precision that they offer. Microfluidic systems offer an exceptionally high level of control of experimental conditions because of their custom-designed architectures and atomization. This increased level of control yields itself to more precise experimentation and accurate results.

Shortened time of experiments

Microfluidic systems allow multiple analytes to be processed at the same time. This simultaneous processing is possible because of the reduced amount of space that each circuit requires. By running multiple circuits at the same time, the amount of time that each experiment takes is greatly reduced, allowing for more efficient processes and increased throughput.

Flexible application

The portability of these highly ordered systems is another advantageous feature they possess. The small size of microfluidic systems allows them to be easily transported, greatly increasing the number of applications they can be used for. Aside from traditional benchtop applications, their portability allows them to be used in point-of-care application as well.

Kelly Pneumatics is a leading supplier of custom flow and pressure control solutions—from digital air flow meters to proportional control valves. Our products are suitable for a wide variety of applications in the medical and semiconductor industries. With over 15 years of experience, you can trust us to provide you with the quality solutions you need. For more information regarding our products, contact us today.